What is the reason for the insufficient strength of concrete discharged from concrete mixing plant

In the process of mixing concrete in concrete mixing station, there are many factors affecting the quality of concrete. Since the quality of concrete directly affects the quality of construction engineering, how to produce high-quality concrete in the concrete production process has become the most concerned issue. As a concrete mixing plant equipment manufacturer, Zhengzhou Jianxin Machinery provides some suggestions for the majority of users here, analyzes the reasons for the poor quality of concrete produced by the mixing station, and finds solutions.

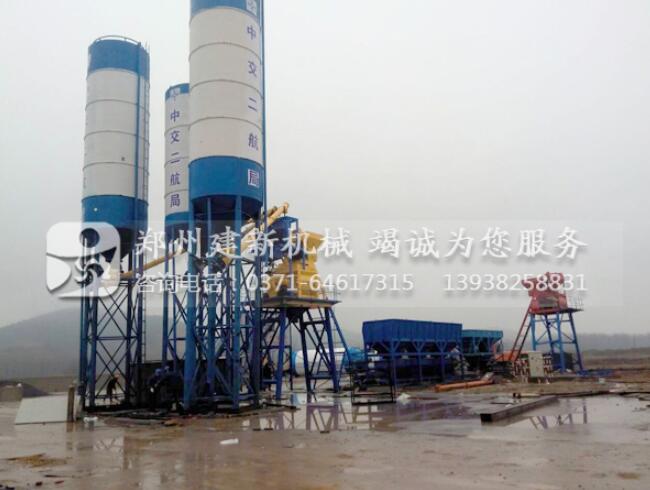

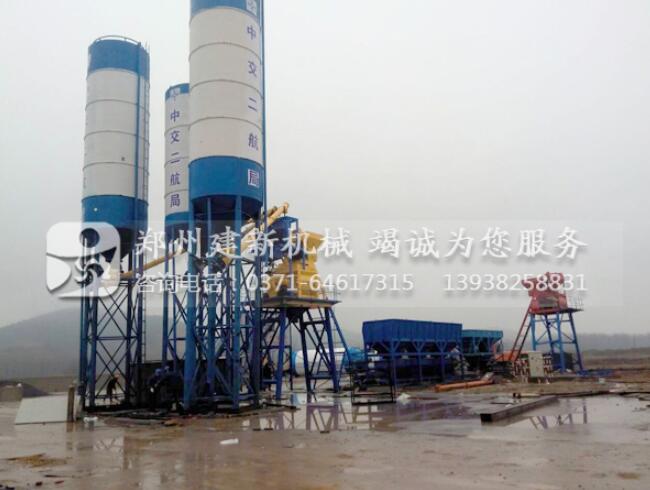

Concrete mixing plant

The first thing to understand is that concrete is made by mixing aggregate of gravel aggregate, cement, water and admixture according to a certain proportion. It can be known that the factors affecting the quality of concrete mainly include the quality of raw materials, the measurement of materials and the accuracy of the ratio. And whether the stirring is uniform or the like. It is not difficult to solve these problems. The proportion of materials for mixing concrete can be determined through experiments. The execution of the mixture requires accurate measurement system and regular inspection and calibration of the metering system to ensure accurate measurement. For the quality of raw materials, it is necessary to strictly screen according to the requirements in the procurement stage of various materials. In addition, the skills training of the concrete mixing station operators should be strengthened to ensure the orderly input of raw materials to produce idealized concrete.

<< Previous:Design of Automatic Control System for Jianxin Concrete Mixing Plant Equipment

<< Next:Concrete mixing plant equipment must be lubricated and maintained by the reducer

Language

Language

Language

Language

Tel:0086-18437125333/0086-371-86598800

Tel:0086-18437125333/0086-371-86598800 Fax:+86-371-86599393

Fax:+86-371-86599393 E-mail: jianxin@zzjxcorp.com

E-mail: jianxin@zzjxcorp.com Address:West 200m of Guangwu Road and G310 National Way intersection, Xingyang-Zhengzhou City, Henan Province, 450100 China

Address:West 200m of Guangwu Road and G310 National Way intersection, Xingyang-Zhengzhou City, Henan Province, 450100 China